The sustainable use of resources can be achieved through a balanced product life cycle. In doing so, it is crucial to know the lifespan and long-term behavior of the materials. The biomaterial research in Teltow has created a method for predicting the long-term behavior of plastics by means of quick tests on ultra-thin layers in combination with computer-assisted models. Thereby, for example, both the degradation behavior and the degradation duration of bioplastics can be determined within a few hours – instead of months or years.

360° of science: Predicting the lifespan of plastics (The video is only available in german)

Note for iOS operating system: For a free look around, please follow the link to our video on Youtube https://youtu.be/hGH6D5rXptY

The sustainable use of resources can be achieved through a balanced product life cycle. In doing so, it is crucial to know the lifespan and long-term behavior of the materials. On the one hand, plastic products can be used for decades, but, on the other hand, the robustness of these products poses challenges for the environment.

The biomaterial research in Teltow has created a method for predicting the long-term behavior of plastics by means of quick tests on ultra-thin layers in combination with computer-assisted models. Thereby, for example, both the degradation behavior and the degradation duration of bacterially created bioplastics can be determined within a few hours – instead of months or years.

Scientists are also examining enzymes on the thin layers which are able to degrade the bioplastic again. Best of all: Some enzymes can also degrade conventional materials such as PET, which is found in plastic bottles. Here in Teltow, the cornerstones for the sustainable use of plastics are being laid down.

Video: Interview with Rainhard Machatschek and Natalia Tarazona (The video is only available in german. You can find the translation below in the transcription of the video)

Predicting the Lifespan of Plastics

A sustainable use of resources can be achieved through a balanced product life cycle. To achieve this goal, it is crucial to know the product lifespan and long-term behaviour. This would spare the environment and advance medicine. Ultra-thin films and simulations are of assistance here.

By Lars Klaaßen

Plastic waste in the form of microplastics, for example, pollutes the environment, mainly the oceans. Some materials are considerably more lasting than originally thought—and more long-lived than would be necessary. Others disintegrate more quickly than expected, something that can be equally as problematic. Knowing when certain plastics would entirely biodegrade and under what conditions would have many benefits. For example: with a suture material that simply dissolves at the desired time after a medical procedure. Temperature, pH value, enzymes, mechanical stress as well as the interaction with cells and tissue have an immense effect on the duration of such processes. “In order to accelerate development of new materials that possess the desired properties and functions, we are working on a prediction method for their long-term behaviours,” says Natalia Tarazona, scientist at the Hereon-Institute for Active Polymers in Teltow. “Our aim is to be able to make quantitative statements in a few hours about polymer degradation behaviour, depending on environmental parameters as well as on chemical composition and structure.”

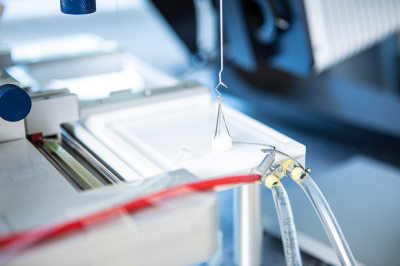

The researchers combine the data obtained through carrying out experiments with computer models to provide predictions for macroscopic shaped bodies. One of these researchers is Dr. Rainhard Machatschek. Photo: Hereon/Gesine Born

To do so, a few micrograms of the material are spread out on nanoscopically thin films that are floating on a water surface. The degradation of the chain-like molecules produces water soluble fragments, which reduce the area of the film. The latter can be measured precisely. The scientists combine this experimentally obtained data with computer models to provide predictions of macroscopic structure. For the full description of the degradation behaviour of medical implants or everyday objects, another component is missing. The transport of small molecule fragments from the material as well as the diffusion of water, which is a prerequisite for the molecular degradation processes, cannot be measured in this experiment. “Multi-scale computer simulations, into which we integrate the results from the ultra-thin films, are suitable for this,” says Tarazona. “In the medium term, we want to know how the long-term behaviour of a material looks in different scenarios even before the production of test specimens.”

“A class of substances that are very interesting to us right now, are polyhydroxyalkanoates,” adds Tarazona. “These PHAs have the advantage over other plastics of biological origin in that they are completely synthesized in bacteria, which can, for example, be fed with agricultural waste.” PHAs were initially brittle and quickly formed cracks. Newer representatives, such as polyhydroxyoctanoate (PHO), are considerably more elastic and flexible. “As very little is known about this PHO’s long-term behaviour, we looked at the material under different environmental influences,” says Tarazona. “It is completely degradable.”